Zesty Orange Natural Extract 35ml

Read More

.

Food is an essential part of everyday life which means that you have the responsibility of looking after your customers and the wider community. Therefore, it is paramount to understand what the best way is to prevent poor food safety.

There are many reasons why good food safety is important. It aids your reputation and your brand integrity, boosts employee wellbeing, and increases your chances of long-term business viability. These factors are essential for building and maintaining a lucrative business.

However, the most important reason is that preventing poor food safety is essential for public health. Poor hygiene can lead to foodborne illnesses, which can cause an array of health issues that range from mild to fatal. Not only will you be causing harming your customers but there can be long term consequences of poor food safety practices such as legal battles, financial compensation, and a tarnished brand.

Not cleaning thoroughly is one of the most common reasons why food businesses are prosecuted, following the 4 c’s of food safety will help you to avoid this happening.

• Clean and disinfect your food preparations areas including equipment, especially after handling raw food.

• Clean as you go, before, during, and after any task. Remember “ABCD” which stands for Always Be Closing Down, by maintaining clean work areas you will stay on top of messes that occur and prevent unnecessary build up.

• Use suitable cleaning and disinfection products according to the manufacturer’s instructions. Look for products with BS EN 1276 or BS EN 13697 as these comply with the BS EN standards.

• Regularly dispose of food waste to the correct bins.

• Create a cleaning schedule to make sure surfaces and equipment are cleaned when required.

Cooking your foods to accurate temperatures kills harmful bacteria in food and is one of the best ways to prevent food-borne illnesses.

Most types of meat require thorough cooking as harmful bacteria is present in the middle of the product. There are a few exceptions to this rule including whole cuts of beef and lamb like steaks, cutlets and non-rolled roasting joints. It is usually only the surface of these products that can be contaminated. You should therefore cook and seal the meat’s surface to kill any bacteria.

For the following products:

• Poultry, for example chicken or turkey

• Duck and other fowl

• Pork

• Rolled joints

• Products made from minced meat, such as burgers, sausages and kebabs

• Kidneys, liver and other types of offal

The following requirements should be met before serving:

• They are steaming hot all the way through

• Any juices run clear

• There is no pink or rare meat inside

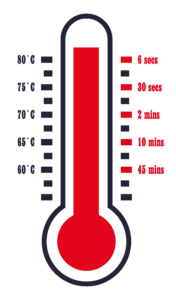

The following cooking temperatures should be met in accordance with the timings below:

The chart below shows how long it takes for bacteria to be killed at different temperatures.

• 60°C for 45 minutes

• 65°C for 10 minutes

• 70°C for 2 minutes

• 75°C for 30 seconds

• 80°C for 6 seconds

Creating systems within your business to chill and freeze food properly will help to stop the growth of harmful bacteria.

The following foods need to be kept chilled to keep them safe:

• Foods with use-by dates.

• Cooked dishes.

• Ready-to-eat foods like salads and desserts.

Chilling is most commonly practiced by:

• Following the manufacturer’s storage instructions.

• Putting foods in the fridge straight away.

• Cooling cooked foods as quickly as possible before putting in the fridge to avoid raising the internal temperature of the fridge.

Following the correct procedure for freezing produce is also essential:

• When receiving deliveries, ensure that frozen foods are put into the freezer as a priority.

• Fresh food must be frozen as soon as it has been delivered or prepared.

• Divide larger portions of food into smaller ones using bags or containers. This will speed up the rate at which it freezes as well as defrosts.

• Correct labelling of frozen goods is essential. Make sure foods with a use-by date are frozen before the use-by-date is past and make sure the date of freezing is clearly noted. Change the use-by date to a best-before date as frozen produce keeps its quality for some time after the best-before date.

Cross-contamination occurs when harmful bacteria is spread between work areas, equipment and food. It is most commonly found when raw food comes into contacts with ready-to-eat food either through direct contact, drippings, or inadequate disinfecting. The idea that properly cooked food can no longer be contaminated is incorrect as cross-contamination is very common in food businesses. In this section we will explore how to prevent this.

How can food handlers reduce bacteria?

• Disinfecting all work surfaces, chopping boards, equipment, and washing hands thoroughly before and after each task.

• Using the allocated equipment depending on the task being performed.

• Always keeping raw and ready-to-eat foods separate.

• Storing raw foods beneath ready-to-eat foods in the fridge. Not following this storage practice could cause cross-contamination.

• Using separate cleaning materials (cloths, sponges, etc.) for raw and ready-to-eat foods.

Why is avoiding cross contamination so important?

• Failure to prevent poor food safety can lead to legal consequences, including fines or shutdowns.

• A single outbreak of foodborne illness can tarnish a restaurant’s reputation, leading to a loss of customers and revenue.

• Cross contamination can also affect individuals with food allergies. Even trace amounts of allergens can cause severe allergic reactions. Proper handling and prevention of cross contamination are essential for accommodating customers with food allergies.

• Providing a hygienic, safe environment for you staff to work in can boost morale and efficiency.

.